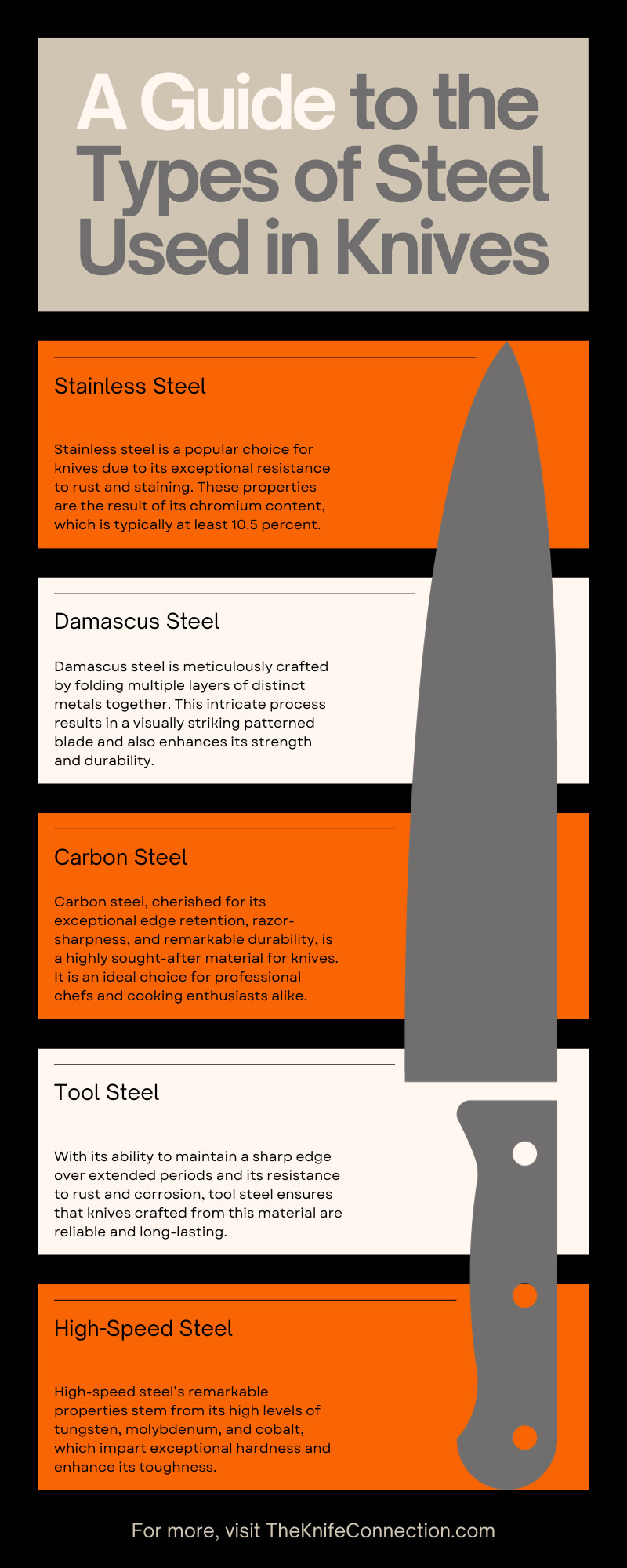

A Guide to the Types of Steel Used in Knives

Jan 17 2024 - 7:55

When you’re comparing knives, materials play a critical role in their quality, durability, and performance. Understanding the different types of steel you might find in knives can help you make a more informed decision when purchasing one. This guide will cover some of the most common steel types used in knives as well as their characteristics.

Stainless Steel

Stainless steel is a popular choice for knives due to its exceptional resistance to rust and staining. These properties are the result of its chromium content, which is typically at least 10.5 percent. Not only does stainless steel exhibit remarkable durability and resistance to wear and tear, but it’s also easy to sharpen and maintain. It is important to note that stainless steel is not as hard as some other steels, resulting in a relatively quicker loss of sharpness. However, its overall performance and longevity make it a popular choice among knife enthusiasts and professionals alike.

Damascus Steel

Damascus steel, renowned for its exceptional quality, is meticulously crafted by folding multiple layers of distinct metals together. This intricate process results in a visually striking patterned blade and also enhances its strength and durability. With its exceptional corrosion resistance and edge retention, Damascus steel surpasses ordinary blades in performance. Each layer of metal contributes unique properties, optimizing the overall performance of this extraordinary steel.

Carbon Steel

Carbon steel, cherished for its exceptional edge retention, razor-sharpness, and remarkable durability, is a highly sought-after material for knives. With its elevated carbon content, carbon steel exhibits unparalleled hardness and toughness, making it an ideal choice for professional chefs and cooking enthusiasts alike. Not only are these knives easy to sharpen, but they also maintain an impressively keen edge that effortlessly glides through any ingredient. However, carbon steel knives are prone to corrosion and necessitate regular maintenance to prevent rusting and ensure continued performance.

Tool Steel

Tool steel, a type of high-carbon steel, is famous for its exceptional strength and durability, making it the perfect choice for a wide range of heavy-duty applications. With its ability to maintain a sharp edge over extended periods and its resistance to rust and corrosion, tool steel ensures that knives crafted from this material are reliable and long-lasting. Although working with this material requires additional expertise compared to other metals, the unparalleled performance and longevity of tool steel knives justify their higher price point.

High-Speed Steel

High-speed steel (HSS) is a type of steel renowned for its exceptional resistance to wear and abrasion. Its remarkable properties stem from its high levels of tungsten, molybdenum, and cobalt, which impart exceptional hardness and enhance its toughness. This unique combination of characteristics makes high-speed steel an ideal choice for many applications, including power tools, drill bits, and, of course, knives. Thanks to its superior durability and cutting performance, high-speed steel continues to be a favorite material in various industries where precision and reliability are paramount.

Powder Steel

Powder steel, also known as powdered metallurgy steel, is meticulously crafted through a unique process. To create this exceptional material, molten steel is atomized into a fine powder, which is then carefully pressed together. The resulting steel exhibits outstanding characteristics, including remarkable edge retention and hardness. As such, it’s a highly coveted material for knives, as powder steel blades offer unparalleled performance and cutting ability. However, these knives tend to be on the pricier side due to the intricate manufacturing process involved and the need for specialized equipment to produce them.

VG-10 Steel

VG-10 steel, known for its exceptional quality, is a Japanese steel that finds widespread application in knives, especially in the realm of high-end chef knives. This exquisite steel boasts elevated carbon, cobalt, and vanadium levels, imparting incredible sharpness, edge retention, and durability. Moreover, VG-10 steel showcases remarkable resistance to corrosion and staining, making it an impeccable choice for discerning knife enthusiasts seeking excellence in their culinary endeavors.

AUS-8 Steel

AUS-8 steel, better known as Aichi Steel, is another highly regarded type of Japanese stainless steel in the world of knives. Known for its exceptional toughness, durability, and resistance to corrosion, AUS-8 steel has become a popular choice among knife enthusiasts and professionals alike. This steel is characterized by its hardness, which allows for easy sharpening and provides excellent edge retention, ensuring long-lasting cutting performance. With its superior cutting ability and versatility, AUS-8 steel has found its way into various applications, including sports and hunting knives, where precision and reliability are vital.

S30V Steel

Last but not least, we have S30V steel, which is widely recognized and favored in outdoor settings thanks to its exceptional strength and durability. This steel variant boasts a high carbon content, endowing it with notable hardness and resistance against wear and tear. Moreover, S30V steel knives are both easy to sharpen and retain their sharpness over time, making them a practical choice for intricate tasks such as skinning and field dressing. With its superior performance and reliability, S30V steel remains a top choice for discerning outdoor enthusiasts and professionals alike.

How To Choose the Right Type of Steel

The right type of steel for your knife will depend on many factors, but your primary focus should be the intended use of the knife and your personal preferences. For professional chefs or culinary enthusiasts who prioritize edge retention and sharpness, carbon steel or VG-10 steel would be exemplary choices.

If you’re seeking a knife for outdoor usage or heavy-duty applications, S30V steel or tool steel, both known for their durability and strength, would be ideal. For those who prefer easy maintenance and corrosion resistance, stainless steel or AUS-8 steel would serve well.

Additionally, if you’re seeking a unique and visually striking blade with superior performance, Damascus steel is worth considering. However, for those willing to invest in high-end knives and seek outstanding performance across all parameters, powder steel is highly recommended.

In the end, you must remember that each type of steel has unique strengths and weaknesses. None is the perfect all-around material, but some will perform better than others for specific functions. So whether you’re looking for a quality Winkler fixed blade for outdoor survival or a simple pocket knife for around-the-house usage, there is a steel type that’ll be perfect for you.